Yacht paint is the most labor extensive process in a Yacht building process. It starts with a high end fairing and ends with a high quality paint like Awlgrip.

The full process requires qualified teams as well as throrough project management. A single default during fairing will drastically point out from the hull once the finish coats have been applied. A low grade work will result in blisters, fish eyes, unfilled pin holes. The worst being an over thick fairing which will broke out the hull by chunk.

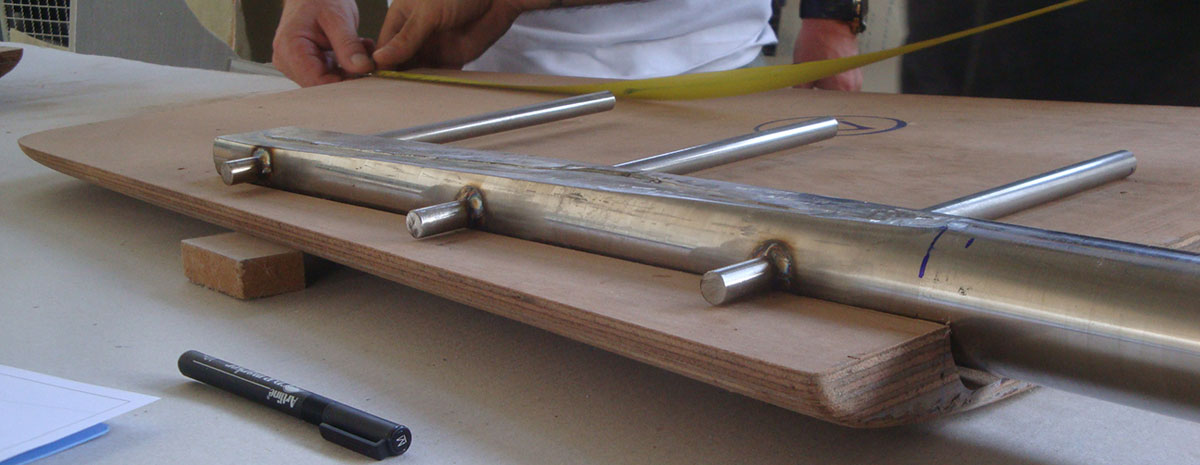

To insure high quality work, Serenity shipyard only uses epoxy and epoxy compatible fairing compound of the highest quality. We observe a strict control on the fairing thickness. No additional fairing compound is applied before the sanding teams have reached through sanding the fiberglass. Guide coating is continuously used during the sanding process. As soon as a perfect fairing as possible has been achieved, the first High Built primer is applied, sanding starts again as to spot all imperfections. We then apply the last primer. At that stage we do build a dust free tent around the boat using imported heat shrink film. Extractors, filters and aircon are installed around the tent as to insure a dust free environment and moisture control.

Yacht pain is an expensive process which cannot be left to be done by unqualified teams. It does require qualification, training, technical knowledge, a lot of experience and above all an understanding that the best built yacht will llook ugly if the paint work is not to standard.

Buy Kicks | Klær Nike